FAITES NOTRE CONNAISSANCE

La seule entreprise de plaquettes de frein frittées pour éoliennes certifiée en Amérique du Nord.

KUMA Brakes conçoit et fabrique des plaquettes de frein à durée de vie optimale, fabriquées à partir de poudres métallurgiques pour les applications éoliennes. Nos produits certifiés sont formulés pour avoir une haute résistance à la corrosion et sont soumis à des processus de contrôle de qualité rigoureux pour garantir à nos clients un produit de la meilleure qualité. En conséquence, nos plaquettes de frein nord-américaines sont acceptées par l’un des principaux fabricants mondiaux sur le marché d’équipement d’origine (OEM) : General Electric.

Notre histoire

Nous innovons

KUMA Brakes a été fondé en 2010 par des ingénieurs du secteur de l’énergie éolienne dans le but de concevoir des plaquettes de frein innovantes et de qualité supérieure pour approvisionner les fabricants locaux. En collaboration avec l’Université Laval et la Technische Universität Berlin, il a fallu 5 ans de recherche et de développement pour trouver la combinaison parfaite de matériaux de friction.

Nous concevons

En 2015, nous étions prêts à concevoir des plaquettes de frein haute performance et avons ouvert notre usine de production au Québec. Grâce à ses capacités de production 100 % internes et à son offre complète de pièces de remplacement, KUMA Brakes devient le guichet unique pour tous les besoins en matière de plaquettes de frein pour éoliennes.

Nous performons

Au fil des ans, nous avons étendu notre production à l’échelle internationale et développé des relations à long terme avec les leaders du marché mondial de la fabrication d’éoliennes. Actuellement, les plaquettes de frein de KUMA Brakes sont utilisées sur plus de 50 % des éoliennes nord-américaines et continuent d’atteindre de nouveaux sommets dans le monde entier.

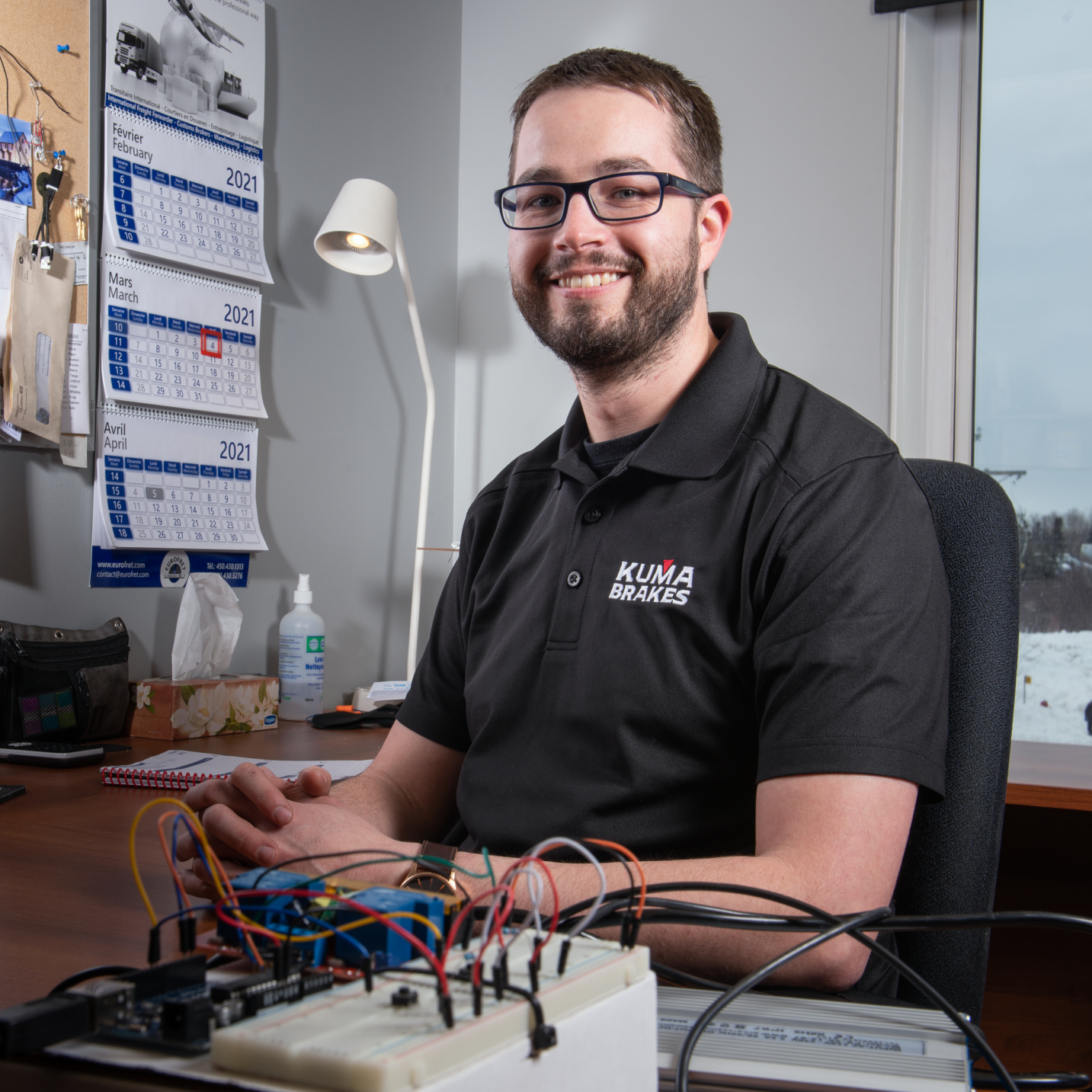

Le moteur de notre réussite.

Rencontrez les membres de notre équipe hautement qualifiée et dévouée.